Traditionally, an expanded metal is perceived as a metal material which possesses diamond shaped holes. They are produced using an expandable machine. It uses both a stretching process and pressurized slitting to change sheets of metal and coils into an expanded mesh. Generally, metals can be expanded into a wide range of patterns and thickness depending on the intended application. This process of expanding metals was patented by Hartlepool, the UK in 1880’s. A part from metals, other materials e.g. plastics or ductile materials can also be expanded. Expanded metals are available in both ferrous and non-ferrous metals with varying sizes. They are used in applications which require both strength and flexibility, weight reduction and cost reduction. Cutting this metals can be such a difficult and challenging process especially if you do not follow the correct procedure and possess the desired cutting tools. Cutting these types of metals is easy though it requires a bit of effort and may take a little time too.

Get the right tools.

Like any other cutting processes, to cut expanded metal successfully, you have to choose the right tools and equipment which will aid the cutting process. Some of these tools and equipment include:

Cutting tool; there are very many grinders which are available in the market. Choose a grinder depending on the nature and size of the expanded metal to be cut.

Measuring device; you can opt for either a ruler or a tape measure. You will use it to determine the exact length of the metal you would wish to cut.

Clamps; they help to hold the metal in position during the cutting process.

Safety glasses; they protect the eyes from tiny particles of metals which could enter the eye during the cutting process.

Gloves; protect hands holding both the grinder and the wire to be cut.

Do not assume that cutting expanded metal is a simple process and thus safety equipment is not necessary; safety is a priority. Before you begin the process, ensure that all tools are in good working condition.

Identify the type of expandable metal you would wish to cut.

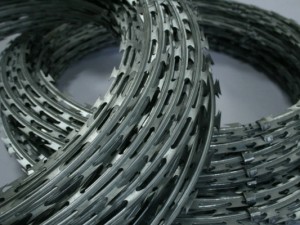

There are very many types of expandable metals available in the market. Every metal has been designed for a specific application. Some of the most common types of metals include:

The standard or regularly expanded metals; these metals are manufactured using a press which cuts and stretches the solid metal simultaneously. This results into strips in a diamond pattern. This pattern increases air circulation, distributes weight evenly throughout the metal surface and enhances both strength and rigidity of the metal. They are used in wide range of applications which include security applications such as in warehouse enclosure, safety guards especially when it comes to preventing unwanted objects from entering a particular area.

Flattened expandable metals; the standard expandable metals can be processed further (for the second time) using a cold rolling press. These metals have both smooth and level surface. Cold rolling reduces metal thickness making the metal ideal for ventilation devices, making cages and fencing.

Expanded metal mesh; they are also available in a wide range of gauges and shapes. They are used mainly used for both architectural and decorative purposes. They are also available in a wide range of sizes and shapes. Such metals may require special cutting tools unlike for the case of the standard types.

Expanded metal grating; these types of metals are created using low carbon steel plates and they are of heavy gauge. They are mostly used in making walkways, machine platforms or areas which tend to experience a high level of pedestrian traffic. Their design offers durability with better traction and low maintenance costs.

To cut expanded metal efficiently, it is important to know the kind of metal you would wish to cut. These metals also made from different types of metals such as steel, aluminum, copper etc. They vary in strength and other physical properties. Therefore, while choosing the type of cutting equipment, all these factors must be considered. Generally, this knowledge will help to determine the right kind of tool to be used during the process besides designing and appropriate cutting procedure.

Take measurements.

You need to know the exact size of the metal you need cut. Place the metal on a flat surface and use a tape measure to mark the exact portion of the metal you need.

The measurements must be very accurate to ensure that no or very small portion of the metal goes to waste. Place a ruler and make permanent marks on the metal using a marker pen. Sometimes, marking tape can also work. These marks will act as the cut line. In most cases, it is much easier to cut these metals along the joints though it’s not critical. The cutting line will depend on the type of the application.

May be you can opt for 1,220 centimeters (480.3 in) by 2,440 centimeters (960.6 in); depending on the nature of the application. The shape can be rectangular, triangular, circular etc.

In any engineering or technical job, the accuracy of the final product will be determined by the accuracy of the measurement which had been taken. The measuring device must be accurate. To achieve these high level of accuracy, you must know how to use the measuring device.

In situations where the expanded metal has been rolled, unroll the metal carefully on a flat surface to obtain accurate measurements. If possible, you can fix one end of the metal. As you unroll the expanded metal to take the measurements. Be sure to wear a pair of gloves to protect your hands from the sharp edges of the metal.

Begin the cutting process.

This is the most critical part of the entire process. Before you begin to cut expanded metal, clamp it tightly. This will prevent any movement during the cutting process. During the cutting process, the cutting tool saw or drill will exert some amount of force on the metal which may force it to move sideways. When tightly clamped, it will be possible to cut the piece of metal along the marks and hence making accurate cuts which will reduce the number of wastes.

It is advisable to have an apron or any protective cloth to protect the body from tiny pieces of metals; wear safety glasses to protect the eyes, gloves to protect the hands and safety boots to protect the feet. When you are safe, you will be confident and thus, there will be higher chances that you will concentrate on the cutting process. There will be higher chances of making accurate cuts.

The grinding process produces a lot of heat which may make the piece of metal depending on the size to turn red-hot. It is advisable to give the surface sometime to cool before touching it. Furthermore, depending on how you hold the cutting equipment, the resulting surface can also be very sharp and it may also cut your finger or the gloves. Never slide your finger along the edge of the cut surface.

To cut expanded metal more conveniently, place the portion to be cut on a raised surface. This will ensure that you do not cut working surface. Some surfaces such as rocks tend to damage the blades of the cutting tools due to their hard surface.

Some expanded metals may not be strong enough to support their weight when their surfaces have been raised. Place another material near the surface which had been marked, preferably wood since it is soft. Alternatively, you can clamp both sides of the metal such that the marked surface lies between the clamps. Tighten the clamps to make the surface tight and flat to make accurate cuts.

When you want to cut a small piece of metal from a larger sheet, begin all your cutting process from one edge of the metal. In most cases, if you choose any section within the center or any point away from the edges, there will be higher chances of wasting quite a substantial amount of metal. Remember, minimizing wastage will be a sure way to reduce expenses.

To cut expanded metal, you will require a cutting tool.

Cutting tools are very dangerous especially if they have not been handled carefully. You must handle cutting tools with a lot of precautions. The very first step is to ensure that the cutting tool is in good condition; it is functioning as desired.

For instance, for the case of a grinder, the grinding disk must be tightened firmly to avoid chances of the grinding disk flying away during the process. The cutting device must be sharp to obtain a good finish.

When you opt for other advanced techniques such as laser cutting, you must also ensure that the entire machine is also functioning as accurately. More importantly, you must know how to operate the laser cutting machine. Most cutting equipment produce a lot of sparks which you must be very cautious about; a reason why you must have goggles and protective clothing.

Unlike cutting other solid metals, expandable metals have so many gaps. Each gap on the extended metal will cause the cutting tool to move forward faster more so when you apply excessive force. Remember to hold the cutting tool firmly and do not apply a lot of force which will make the cutting tool to go off the marked line. Always keep a steady hand as you work down the metal and continue cutting until you reach the final mark. The expanded metal will separate and the job will be complete. You can grind the edges of the metal which had been cut to make the sharp edges blunt since this will also minimize chances of someone else being cut by the sharp edges.

Cleaning the workshop.

Separating the required piece of expanded metal does not mean that the job is complete. Your work area must be kept clean free from small pieces of metal since they may be hazardous. Collect all the unused pieces of metals and dispose of them appropriately. The unused section of the expanded metal should be taken back to the store. *Clean all tools and equipment and store them appropriately too. Cleaning tools and equipment will ensure that your cutting tools serve you for a long time.

To cut expanded metal, you do not require a lot of experience since these are very easy and simple steps one can easily follow. However, it comes with quite a number of risks and there are higher chances of getting injured if one happens to ignore any of these precautions which have been highlighted above

Sources – wiki how