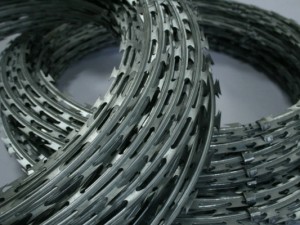

Perforated metal

Perforated metal, also known as a perforated sheet, perforated plate, or perforated screen, is sheet metal that has been manually or mechanically stamped or punched to create a pattern of holes, slots, or decorative shapes. Materials used to manufacture perforated metal sheets include stainless steel, cold rolled steel, galvanized steel, brass, aluminum, tinplate, copper, Monel, Inconel, titanium, plastic, and more.

The process of perforating metal sheets has been practiced for over 150 years. In the late 19th century, metal screens were used as an efficient means of separating coal. Unfortunately, the first perforators were laborers who would manually punch individual holes into the metal sheet. This proved to be an inefficient and inconsistent method which led to the development of new techniques, such as perforating the metal with a series of needles arranged in a way that would create the desired hole pattern.

Modern day perforation methods involve the use of technology and machines. Common equipment used for the perforation of metal include rotary pinned perforation rollers, die and punch presses, and laser perforations

Micro perforated plate

A Micro Perforated Plate (MPP) is a device used to absorb sound, reducing its intensity. It consists of a thin flat plate, made from one of the several different materials, with small holes punched in it. An MPP offers an alternative to traditional sound absorbers made from porous materials.

Structure

An MPP is normally 0.5 – 2 mm thick. The holes typically cover 0.5 to 2% of the plate, depending on the application and the environment in which the MPP is to be mounted. Hole diameter is usually less than 1 millimeter, typically 0.05 to 0.5 mm. They are usually made using the micro perforation process.

Operating principle

The goal of a sound absorber is to convert acoustical energy into heat. In a traditional absorber, the sound wave propagates into the absorber. Because of the proximity of the porous material, the oscillating air molecules inside the absorber lose their acoustical energy due to friction.

An MPP works in almost the same way. When the oscillating air molecules penetrate the MPP, the friction between the air in motion and the surface of the MPP dissipates the acoustical energy.

Comparison with other materials

Traditional sound absorbers are porous materials such as mineral wool, glass or polyester fibers. It is not possible to use these materials in harsh environments such as engine compartments. Traditional absorbers have many drawbacks, including pollution, the risk of fire, and problems with the useful lifetime of the absorbing material.

The main reason why Micro Perforated have become so popular among acousticians is that they have a good absorption performance but without the disadvantages of a porous material. Furthermore, an MPP is also preferable from an aesthetic point of view.

History

For a while, perforated metal panels with holes in the 1 – 10 mm range have been used as a cage for sound-absorbing glass-fiber bats were large holes let the sound waves reach into the absorbent fiber. Another use has been the creation of narrowband Helmholtz absorbers which can be tuned by hole size and the dimensions of the hole distance and air gap behind the panel. However, when the hole dimensions are in the region of 0.05 – 0.5 mm, the narrow absorption peaks become much wider, making the additional fiber absorber more or less unnecessary, while still maintaining a very high absorption factor. By varying geometrical and material parameters, the acoustical performance can be tailored to meet a multitude of specifications in various applications.

One early contributor to the theory of micro-perforated plates as sound absorbers was Professor Daa-You Maa.Further possibilities aiming to improve the accuracy of Maa’s original model are currently being investigated. One other major phenomenon that currently being investigated is the nonlinear effect i.e. an MPP behaves differently depending on the magnitude of the incident sound wave

Sources – Wikipedia