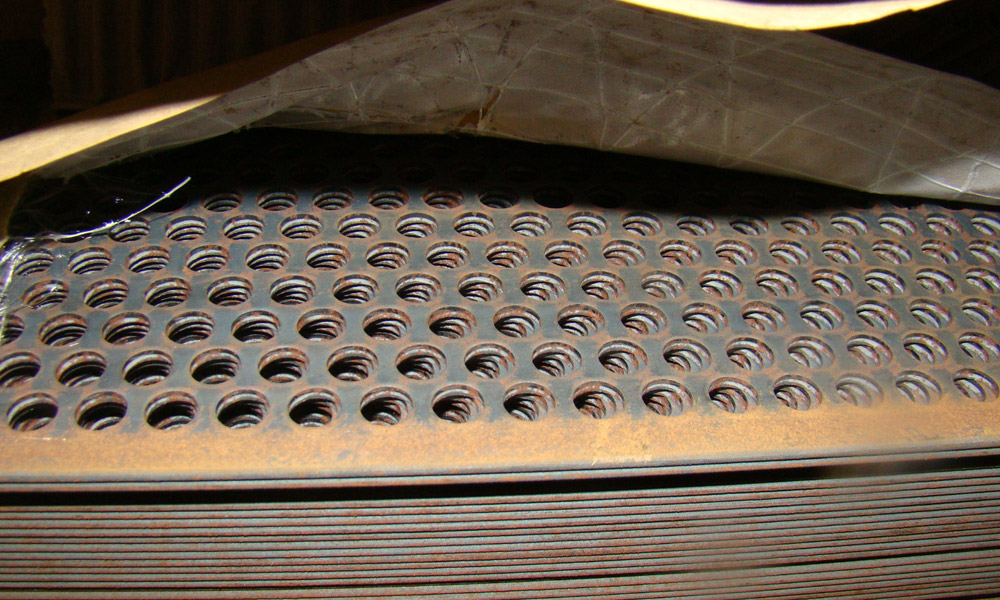

Perforated metal, also known as perforated sheet, perforated plate, or perforated screen, is sheet metal that has been manually or mechanically stamped or punched to create a pattern of holes, slots, or decorative shapes. Materials used to manufacture perforated metal sheets include stainless steel, cold rolled steel, galvanized steel, brass, aluminum, tinplate, copper, Monel, Inconel, titanium, plastic, and more.

The process of perforating metal sheets has been practiced for over 150 years. In the late 19th century, metal screens were used as an efficient means of separating coal. Unfortunately, the first perforators were laborers who would manually punch individual holes into the metal sheet. This proved to be an inefficient and inconsistent method which led to the development of new techniques, such as perforating the metal with a series of needles arranged in a way that would create the desired hole pattern.

Modern day perforation methods involve the use of technology and machines. Common equipment used for the perforation of metal include rotary pinned perforation rollers, die and punch presses, and laser perforations

Applications

- Architectural- infill panels, sunshade, cladding, column covers, metal signage, site amenities, fencing screens, etc.

- Food & beverage- beehive construction, grain dryers, wine vats, fish farming, silo ventilation, sorting machines, fruit and vegetable juice presses, cheese molds, baking trays, coffee screens, etc.

- Chemical & energy- filters, centrifuges, drying machine baskets, battery separator plates, water screens, gas purifiers, liquid gas burning tubes, mine cages, coal washing, etc.

- Material development- glass reinforcement, cement slurry screens, dyeing machines, textile printers and felt mills, cinder screens, blast furnace screens, etc.

- Automotive- air filters, oil filters, silencer tubes, radiator grilles, running boards, flooring, motorcycle silencers, ventilation grids, tractor engine ventilation, etc.

- Construction- ceiling noise protection, acoustic panels, stair treads, pipe guards, ventilation grilles, sun protection slats, facades, sign boards, anti slip flooring

Benefits

The acoustic performance of perforated metal helps people or workers to limit health effects from noise. Studies have shown that perforated metals help reduce sound levels.

Studies have shown that having buildings use perforated metal sheets in front of their façade can bring in one study 29% energy savings (HVAC + Lighting estimated consumption in 1 year) and in the second one 45% energy savings (heating, ventilation, air conditioning). Depending on the location of the building (intensity of the external sun), solar irradiation can be decreased by 77.9%

Sources – Wikipedia