Barbed wire

Barbed wire, also known as barb wire, less often as bob wire or, in the southeastern United States, bobbed wire, is a type of steel fencing wire constructed with sharp edges or points arranged at intervals along the strand. It is used to construct inexpensive fences and is used atop walls surrounding secured property. It is also a major feature of the fortifications in trench warfare as a wire obstacle.

A person or animal trying to pass through or over barbed wire will suffer discomfort and possibly injury. Barbed wire fencing requires only fence posts, wire, and fixing devices such as staples. It is simple to construct and quick to erect, even by an unskilled person.

Barbed wire was the first wire technology capable of restraining cattle. Wire fences were cheaper and easier to erect than their alternatives. One such alternative was Osage orange, a thorny bush which was time-consuming to transplant and grows. The Osage orange later became a supplier of the wood used in making barb wire fence posts. When wire fences became widely available in the United States in the late 19th century, they made it affordable to fence much larger areas than before. They made intensive animal husbandry practical on a much larger scale.

Agricultural fencing

Barbed wire fences remain the standard fencing technology for enclosing cattle in most regions of the US, but not all countries. The wire is aligned under tension between heavy, braced, fence posts strainer posts and then held at the correct height by being attached to wooden or steel fence posts, and/or with battens in between.

The gaps between posts vary depending on type and terrain. On short fences in hilly country, steel posts may be placed every 3 yards (2.7 m), while in flat terrain with long spans and relatively few stock they may be spaced up to 30 to 50 yards (46 m). Wooden posts are normally spaced at 11 yards (10 m) (2 rods) on all terrain, with 4 or 5 battens in between. However, many farmers place posts 2 yards (1.8 m) apart as battens can bend, causing wires to close in on one another.

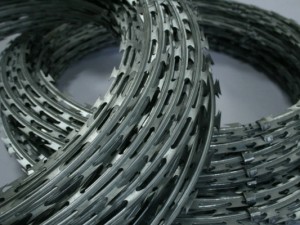

Barbed wire for agricultural fencing is typically available in two varieties: soft or mild steel wire and high-tensile. Both types are galvanized for longevity. High-tensile wire is made with thinner but higher-strength steel. Its greater strength makes fences longer lasting because it resists stretching and loosening better, coping with expansion and contraction caused by heat and animal pressure by stretching and relaxing within wider elastic limits. It also supports longer spans, but because of its elastic springy nature, it is harder to handle and somewhat dangerous for inexperienced fencers. Soft wire is much easier to work but is less durable and only suitable for short spans such as repairs and gates, where it is less likely to tangle.

In high soil fertility areas where dairy cattle are used in great numbers 5- or 7-wire fences are common as the main boundary and internal dividing fences. On sheep farms, 7-wire fences are common with the second from bottom to the fifth wire being plain wire. In India, wire fences must provide passage for dogs since they are the main means of controlling and driving animals on farms.

Human-proof fencing

Most barbed wire fences, while sufficient to discourage cattle, are passable by humans who can simply climb over the fence, or through the fence by stretching the gaps between the wires using non-barbed sections of the wire as hand holds. To prevent humans crossing, many prisons and other high-security installations construct fences with razor wire, a variant which instead of occasional barbs features near-continuous cutting surfaces sufficient to injure unprotected persons who climb on it.

A commonly seen alternative is the placement of a few strands of barbed wire at the top of a chain link fence. The limited mobility of someone climbing a fence makes passing conventional barbed wire more difficult. On some chain link fences, these strands are attached to a bracket tilted 45 degrees towards the intruder, further increasing the difficulty.

Installation of barbed wire

The most important and most time-consuming part of a barbed wire fence is constructing the corner post and the bracing assembly. A barbed wire fence is under tremendous tension, often up to half a ton, and so the corner post’s sole function is to resist the tension of the fence spans connected to it. The bracing keeps the corner post vertical and prevents slack from developing in the fence.

Brace posts are placed in-line about 8 feet (2.4 m) from the corner post. A horizontal compression brace connects the top of the two posts, and a diagonal wire connects the top of the brace post to the bottom of the corner post. This diagonal wire prevents the brace post from learning, which in turn allows the horizontal brace to prevent the corner post from leaning into the brace post. The second set of brace posts forming a double brace) is used whenever the barbed wire span exceeds 200 feet (61 m).

When the barbed wire span exceeds 650 ft (200 m), a braced line assembly is added in-line. This has the function of a corner post and brace assembly but handles tension from opposite sides. It uses diagonal brace wire that connects the tops to the bottoms of all adjacent posts.

Line posts are installed along the span of the fence at intervals of 8 to 50 ft (2.4 to 15.2 m). An interval of 16 ft (4.9 m) is most common. Heavy livestock and crowded pasture demand the smaller spacing. The sole function of a line post is not to take up the slack but to keep the barbed wire strands spaced equally and off the ground.

Once these posts and bracing have been erected, the wire is wrapped around one corner post, held with a hitch a timber hitch works well for this often using a staple to hold the height and then reeled out along the span of the fence replacing the role every 400 m. It is then wrapped around the opposite corner post, pulled tightly with wire stretchers, and sometimes nailed with more fence staples, although this may make a readjustment of tension or replacement of the wire more difficult. Then it is attached to all of the line posts with fencing staples driven in partially to allow stretching of the wire.

There are several ways to anchor the wire to a corner post

- Hand-knotting. The wire is wrapped around the corner post and knotted by hand. This is the most common method of attaching the wire to a corner post. A timber hitch works well as it stays better with wire than with a rope.

- Crimp sleeves. The wire is wrapped around the corner post and bound to the incoming wire using metal sleeves which are crimped using lock cutters. This method should be avoided because while sleeves can work well on repairs in the middle of the fence where there is not enough wire for hand knotting, they tend to slip when under tension.

- Wire vise. The wire is passed through a hole drilled into the corner post and is anchored on the far side.

- Wire wrap. The wire is wrapped around the corner post and wrapped onto a special, gritted helical wire which also wraps around the incoming wire, with friction holding it in place.

Barbed wire for agriculture use is typically double-strand 12½-gauge, zinc-coated galvanized steel and comes in rolls of 1,320 ft (400 m) length. Barbed wire is usually placed on the inner posture side of the posts. Where a fence runs between two pastures livestock could be with the wire on the outside or on both sides of the fence.

Galvanized wire is classified into three categories; Classes I, II, and III. Class I has the thinnest coating and the shortest life expectancy. A wire with Class I coating will start showing general rusting in 8 to 10 years, while the same wire with Class III coating will show rust in 15 to 20 years. Aluminum-coated wire is occasionally used and yields a longer life.

Corner posts are 6 to 8 inches (15 to 20 cm) in diameter or larger, and a minimum 8 feet (2.4 m) in length may consist of treated wood or from durable on-site trees such as Osage orange, black locust, red cedar, or red mulberry, also railroad ties, telephone, and power poles are salvaged to be used as corner posts (poles and railroad ties were often treated with chemicals determined to be an environmental hazard and cannot be reused in some jurisdictions). In India, spruce posts are sold for this purpose. Posts are 4 inches (10 cm) in diameter driven at least 4 feet (1.2 m) and may be anchored in 20 inches (51 cm) square and 42 inches (110 cm) deep. Iron posts, if used, are a minimum 2.5 inches (64 mm) in diameter. The bracing wire is typically smooth 9-gauge. Line posts are set to a depth of about 30 inches (76 cm). Conversely, steel posts are not as stiff as wood, and wires are fastened with clips along fixed teeth, which means variations in driving height affect wire spacing.

Sources – Wikipedia